Providing fabrics printed by inkjet textile printer “FOREARTH” to fashion brand “TELMA” for its 2025 Spring/Summer Collection to be Presented at Rakuten Fashion Week TOKYO

KYOCERA Document Solutions Inc. (President: Hironori Ando) announces that it will provide the fashion brand “TELMA” with fabrics printed with KYOCERA Document Solutions' environmentally friendly inkjet textile printer “FOREARTH”.

Mr. Terumasa Nakajima, who is the designer of the fashion brand TELMA, has won the Grand Prix of the “JFW NEXT BRAND AWARD 2025” [1], which is selected by the Japan Fashion Week Organization with the aim of nurturing and supporting new talents who are expected to play a global role in the fashion industry. He will present his 2025 Spring/Summer collection for the first time in a runway show format at the Rakuten Fashion Week TOKYO organized by the same organization. We are pleased to collaborate with Mr. Terumasa Nakajima, who shared the development concept of our inkjet textile printer “FOREARTH”, and to offer fabrics printed with the product.

The latest TELMA collection, which will be displayed on the first day of the six-day Rakuten Fashion Week TOKYO from September 2 to 7, will be presented at a show on September 2 and then displayed at the “JFW NEXT BRAND AWARD 2025 EXIHIBITION by TELMA” at Shibuya Hikarie's 8/CUBE, Tokyo. An exhibition about “FOREARTH” printed with fabrics used in the show will also be held there.

Background of Collaboration

TELMA designer Terumasa Nakajima is committed to Japanese craftsmanship and often addresses environmental issues by using environmentally friendly materials such as cupra [2] made from recycled fibers and recycled polyester made from twisted yarn [3]. This time, the collaboration was made possible by the company's empathy with the development concept of our inkjet textile printer “FOREARTH,” which contributes to solving long-standing problems in the apparel industry, such as water pollution during textile printing and the massive disposal of fabrics and clothes due to overstocked inventories, while also reducing water consumption to near zero. Through this alignment of values the collaboration was realized.

[1] The “JFW Brand Support Program” launched by the Japan Fashion Week Organization (JFWO) as a new support program for designers.

[2] A recycled fiber made from natural materials.

[3] A bundle of yarn that has been twisted to make it usable as a single strand.

About the designer Terumasa Nakajima

Terumasa Nakajima graduated in 2010 from the Antwerp Royal Academy of Fine Arts, one of the oldest and most traditional of Belgium's art academies, founded in 1663. After working for fashion brands “Dries Van Noten (Belgium)” and “Issey Miyake”, he became independent in 2020 and established the “TELMA”, drawing on his experience with two world-class brands.

In addition to practicing Japanese craftsmanship with a focus on materials, TELMA also considers environmental friendliness an essential issue in the fashion industry and actively incorporates recycled materials and other materials. He is a designer who has received extremely high attention in the industry.

Comment from Terumasa Nakajima

As the awareness for the future of the earth continues to grow, I, as a designer, believe have the responsibility to create products while trying to balance how we can leverage on environmentally friendly design and technology, and also value the stories behind the products so that they can be long lasting and loved for a long time.

Needless to say, the beauty of FOREARTH is that it reduces water consumption by 99% compared to conventional methods. The FOREARTH technology is very innovative, as conventional textile printing and inkjet printing require a large amount of water.

The appeal of FOREARTH is not only that it is sustainable, but also that it has an overwhelmingly wonderful texture. With conventional inkjet printing, it is difficult to find a fabric that is comfortable to wear because of its stiffness and stickiness, but I was surprised by the suppleness of FOREARTH.

Also, I had given up on inkjet printing on mixed weave materials [4] because it was difficult to do so, but I was surprised at the fact that it is possible to print on mixed weave fabrics with different compositions. I was also very impressed with the concept and the technology designed for human wear. Sustainability is only possible when ‘people’ is at the heart. I feel that the collaboration with KYOCERA Document Solutions has taken TELMA's creation one step further. Once again, I am very grateful for this wonderful encounter.

[4] A fabric woven with two or more different types of yarns for the warp and weft.

Rakuten Fashion Week TOKYO

Dates: September 2 (Monday) - September 7 (Saturday), 2024

Venues: Shibuya Hikarie, Omotesando Hills, and other venues

Season: 2025 Spring/Summer Collection

https://rakutenfashionweektokyo.com/en/the39th/

Features of the FOREARTH inkjet textile printer

FOREARTH can reduce water consumption to almost zero when printing fabrics, eliminating the need for large pre- and post-processing machines, steamers, and other equipment required for conventional textile printing. This contributes to a significant reduction in energy consumption and CO2 emissions.

In addition, the system realizes a soft hand with the texture of fabrics, which is important in the textile and apparel industry, and enables high-definition printing on a wide variety of fabrics, including cotton, silk, polyester, nylon, and blended fabrics.

1)Water Free Concept (Reduction of water consumption to as little as possible)

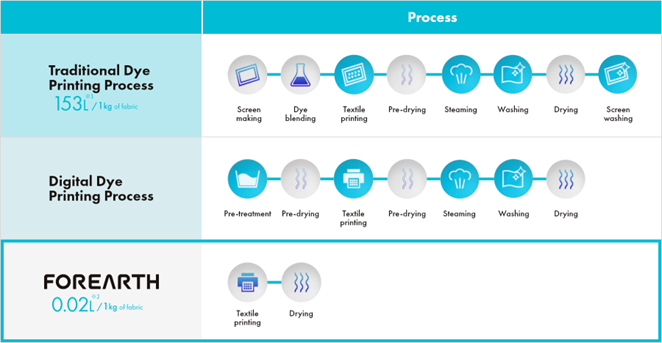

Conventional dye-analog textile printing requires water for four processes, and 153L [5] of water is used per 1 kg of fabric. On the other hand, FOREARTH is water-free because the entire process is completed only by printing and drying, eliminating the use of water in the printing process. The amount of water used for equipment maintenance is also carefully considered, and by installing a circulating belt washing system, cleaning water for the conveyor belt is reused while filtering it through the circulation system. Water consumption per kg of dough has been reduced to 0.02L [6].

[5] Kujanpää , M. & Nors, M. (2014). Environmental performance of future digital textile printing. VTT Technical Research Centre of Finland.VTT Customer Report Vol. VTT CR 04462 14

[6] Based on our own research, 2022

(2) Creative Free (Various Expressions on Various Fabrics)

FOREARTH, which uses Kyocera's proprietary pigment inks and pre- and post-processing solutions, can print on a wide variety of fabrics, including cotton, silk, polyester, nylon, and blended fabrics. Furthermore, the inkjet print head unit always discharges pre-treatment liquid, ink, and post-treatment liquid in sequence to maximize the performance of each and maintain the original softness of the fabric.

In addition, the freedom of digital textile printing, which is not restricted by plates, enables printing of a wide variety of designs with high color and high definition. In addition, the system can be used for a wide range of categories such as ladies' wear, sportswear, kids' wear, and home textiles, thereby expanding creative possibilities and contributing to the creation of new value in the textile and apparel industry.

(3) Location Free (Designs you want now, take shape now)

The entire process of introducing equipment is completed only by printing and drying, eliminating the need for separate preparation processes, steam, washing, etc., as in conventional dye textile printing, thereby significantly shortening the process from design to finished product. This enables printing only the necessary amount of fabrics when needed, and can respond quickly to urgent orders, leading to a reduction in excess production.

Conventional dye textile printing has been installed in locations with abundant water resources. However, the FOREARTH uses only a small amount of water and its space-saving design allows for a wider choice of installation locations. For example, it can be installed near consumption areas, such as on-shore or near-shore locations. This contributes to shorter lead times and lower distribution costs.

Click here for more information about the FOREARTH inkjet textile printer.

Through our sustainable inkjet textile printer “FOREARTH”, we will continue our creative steps to contribute to the world of digital textile printing in order to solve various social issues surrounding the world with the power of technology and to create a better future.

What is “Rakuten Fashion Week TOKYO”?

Fashion Weeks are biannual fashion festivals held in fashion cities around the world, where the latest collections presented at fashion shows and exhibitions are used to create the next season's trends.

Among the world's fashion weeks, those held in Paris, Milan, London, New York, and Tokyo are collectively known as the “five major fashion weeks” and have a great deal of influence.

The fashion week held in Tokyo is “Rakuten Fashion Week TOKYO”.

About Kyocera Document Solutions Europe

Kyocera Document Solutions Europe Management B.V. is a group company of Kyocera Document Solutions Inc., a global leading provider of total document solutions based in Osaka, Japan. The company’s portfolio includes reliable and eco-friendly MFPs and printers, as well as business applications and consultative services which enable customers to optimise and manage their document workflow, reaching new heights of efficiency. With professional expertise and a culture of empathetic partnership, the objective of the company is to help organisations put knowledge to work to drive change.

Kyocera Document Solutions Inc. is a group company of Kyocera Corporation (Kyocera), a leading supplier of semiconductor packages, industrial and automotive components, semiconductor packages, electronic devices, smart energy systems, printers, copiers, and mobile phones. During the year ended March 31, 2024, the company’s consolidated sales revenue totaled 2 trillion yen (approx. US$13.3 billion). Kyocera is ranked #672 on Forbes magazine’s 2023 “Global 2000” list of the world’s largest publicly traded companies, and has been named among “The World’s 100 Most Sustainably Managed Companies” by The Wall Street Journal.